A complete, multi-site cloud manufacturing control and planning system for make-to-stock, make-to-order, engineer-to-order, project-centric, job shop, batch, and repetitive manufacturing.

Why Choose Acumatica for Cloud Manufacturing ERP Software

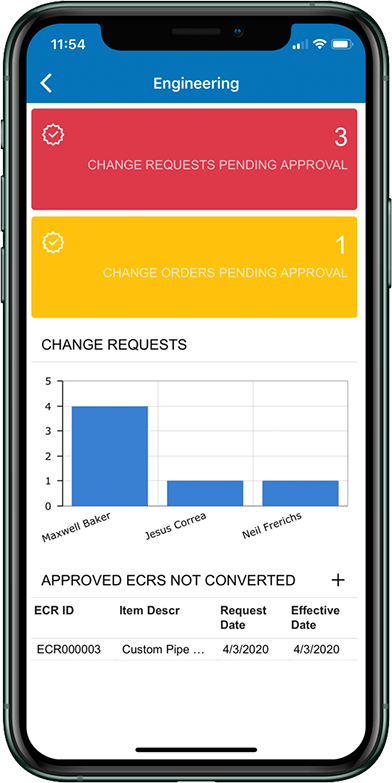

Integrate production planning and the shop floor with customer management, sales orders, inventory, purchasing, accounting, and financial reporting to provide real-time coordination of activities across your entire business. Use your phones and tablets to capture material issues, move transactions, and labor with Acumatica’s mobile app and scanning. Supervisors and manufacturing management can access approvals and monitor production orders, schedules, and material plans anywhere, anytime on the road, in the office, or at home.

Acumatica Manufacturing Edition supports multiple manufacturing methodologies including make to stock (MTS), make to order (MTO), engineer to order (ETO), configure to order (CTO), batch process and more. Customers span every manufacturing industry including automotive, electrical and electronics, industrial machinery & equipment, instruments, fabricated and primary metals, food and beverage, and many others.

The Total Economic Impact™ Of Acumatica

Discover the financial and business benefits of Acumatica Cloud ERP.

The New State of Work in Challenging Times

The right cloud ERP software can keep your virtual teams productive even during a pandemic. Here’s how.

Benefits of Manufacturing ERP Systems for Your Business

-

One Solution for Your Business

Acumatica provides feature-rich cloud manufacturing ERP software. Acumatica Manufacturing Edition extends Acumatica’s Distribution Management, Customer Management, Financial Management, and Project Accounting suites. Acumatica Manufacturing Edition provides real-time coordination of your business activities from one central location, while cross-application integration allows you to have visibility across the entire business wherever you are.

-

Grows with You

Powerful and complete functionality for make-to-stock, make-to-order, engineer-to-order, project centric, job shop, batch, and repetitive manufacturing adapts to your business as you grow and change.

Exercise full control from engineering change request to engineering change order to engineering change notice with approvals throughout each step in the process.

-

Meet Your Schedules

Forecast demand while optimizing resources for effectiveness and cost control by planning with our manufacturing ERP software, including a full-suite of modules. Use MRP and APS to balance material requirements with production schedules.

-

Visualize Schedules

Visualize your production schedule with a graphical view of production order schedules by work center and machine. Adjust constraint dates and priorities and firm schedules from the visual schedule board.

-

Track Your Costs

Track material and labor costs as you manage your products. Compare standard and planned production costs to actual costs of production.

-

Capable to Promise (CTP)

Use Advanced Planning and Scheduling logic to determine how many units of an item will be available by a date or calculate availability dates for a quantity of items based on finite capacity constraints, material availability, and vendor lead times.

-

Pre-Assign Lot and Serial Numbers

Create and preassign lot and serial numbers for finished goods using configurable number masking.